ACP Fabrication Guide

We provide detailed information on ACP sheet price with fitting, ensuring an affordable solution without compromising on quality.

We've introduced 'Story Between the Layers - a Technical Handbook on Metal Composite Panels' to guide our Fabricator community with error-free ACP sheet installation. The Handbook has been enriched with information regarding the chemical, physical and mechanical properties of primary metals used to make different Composite Sheets. It sheds light on the properties of Metal Composite Panels; We have included everything from the right ACP installation methods to the best method of facade beautification for each type of Metal Composite Panel (for both interior and exterior).

Aludecor ACP sheet features weather-proof performance, superior flexibility and zero undulation. By applying the correct and expert-recommended Fabrication techniques, Fabricators can ensure that Aludecor ACP sheets are at their best!

The following guide sheds light on the correct ACP sheet fixing for Aludecor ACP boards.

Aludecor ACP boards can be cut easily by panel saws or running saws. One must make sure that only the carbide tip blade that has been designed especially for Aluminium is used for optimum results.

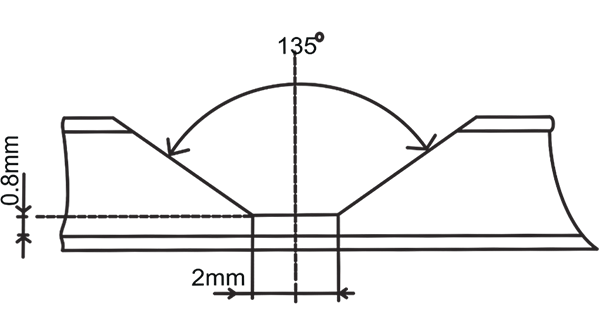

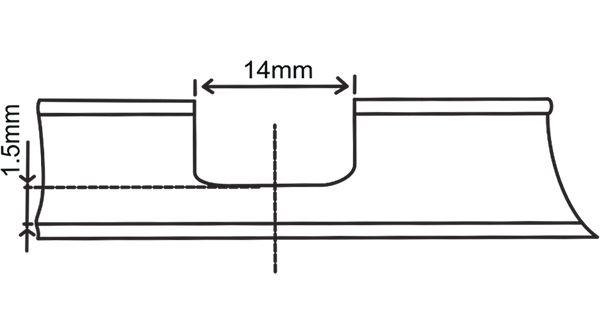

Aludecor ACP boards are compatible with CNC Routing Machine or Panel Saw for mass grooving production. For U-Grooving, leaving 0.2 to 0.4mm of the core material is necessary. On the other hand, for 90° bends, we recommend 110° of grooving angle only.

Aludecor ACP boards that have been transformed into grooved panels must be folded with a Folding Jig, Plate Punch or Press Brake. The grooved panels should only be folded up on a flat table to secure a straight line on folded corners.

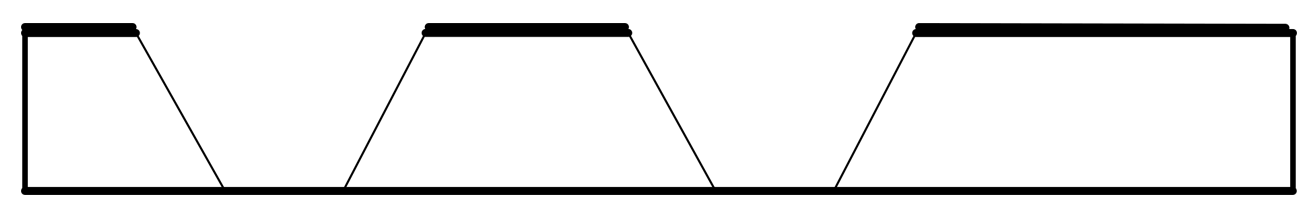

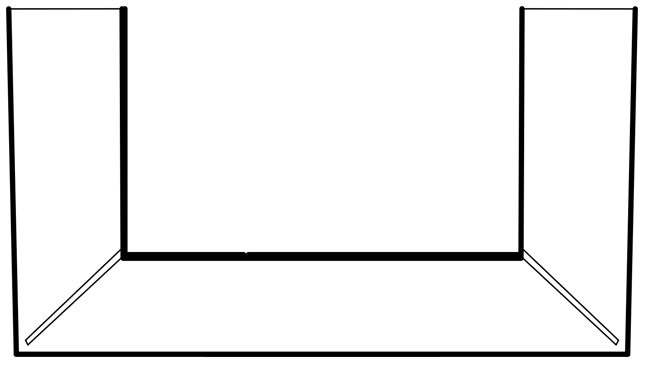

Figures shown below shows the common type of bending of ACP board.

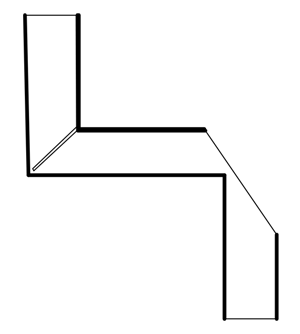

Aludecor ACP board can be easily installed by the Rout and Return method. The ACP boards must be folded to form a tray-type panel. A continuous V-shaped routed groove is created along the entire panel perimeter at a distance of 25 mm from the panel edge. After routing, only a face skin and a minimum thickness of 0.51mm of core material are seen to be left.

Next, the edges are folded after removing the corners in order to create 25mm deep “pan” or cassette. The panel units are stiffened by riveting the corners with aluminium angles.

The next step involves pre-punched aluminium clip angles being attached on the centre to the returned pan edges at approximately 305 mm. The clip angles help transfer the wind load on the panel into the structural supports. To allow for sequential installation, clips are staggered from one panel to the next.

Rout and Return joints must be minimum 16mm wide to ensure smooth thermal movement. Aluminium clip angles at fastener connection points must acquire slotted holes for natural thermal movement. The Rout and Return joints are, at last, caulk sealed for superior protection against moisture and air.

If required Pasting system method of installation can be used shown below.

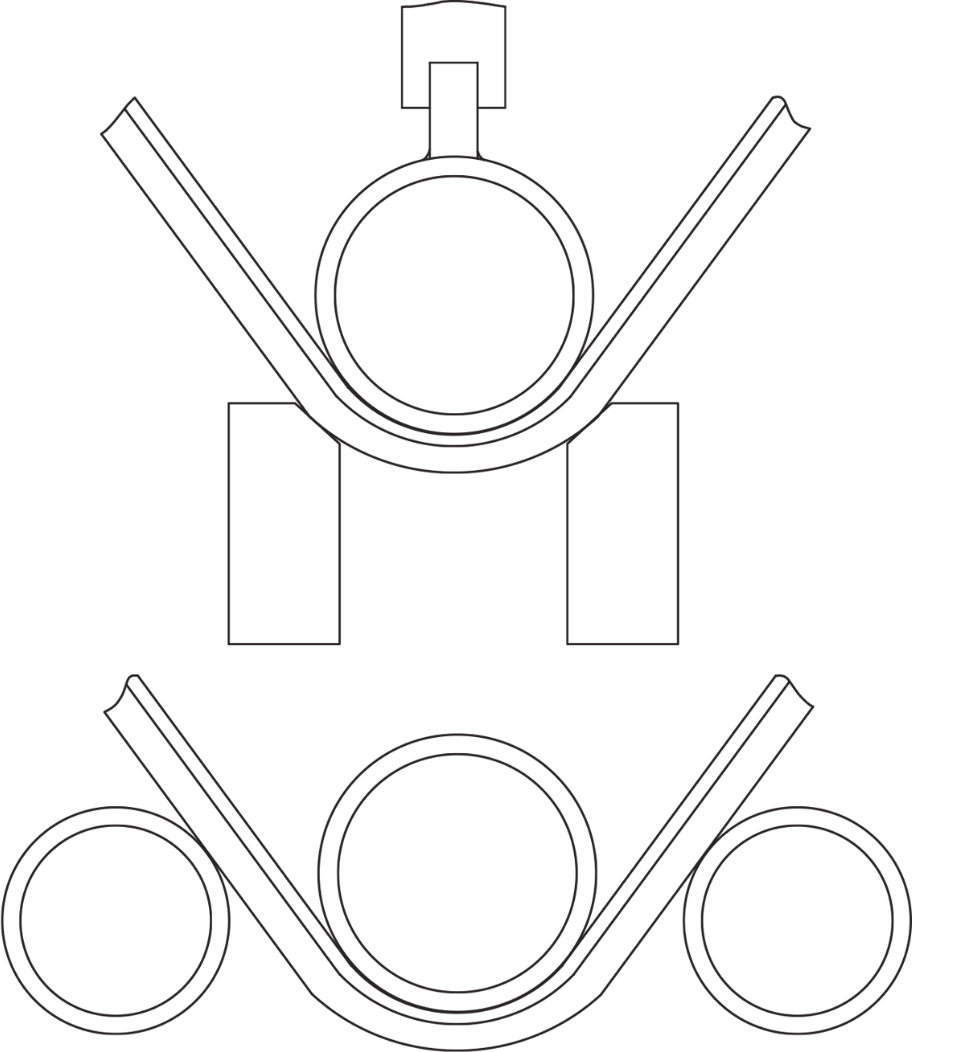

Aludecor ACP boards must be bent with a Press Brake that is paired with a top die for the desired radius.

l min = d x 5

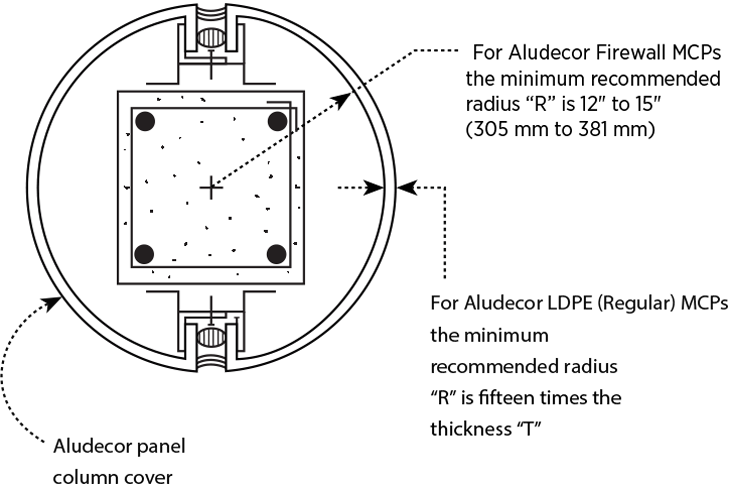

r min = t x 15

t: Aludecor Panel Thickness

Ideal Mould Width (n) = (2xt) + (Roll Radius) + (Foil Thickness) +15 mm

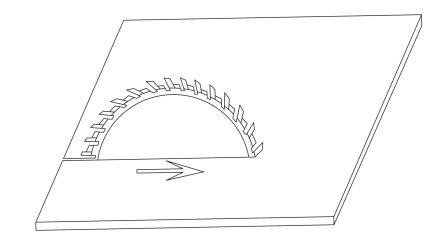

Aludecor ACPs must be grooved and slit at the curving edges before bending by a Three-roll Bender. The Three-roll Bender is ideal for larger bending radius.

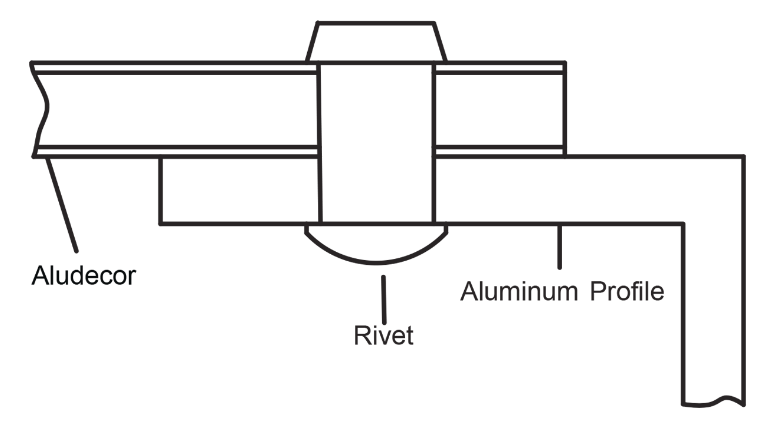

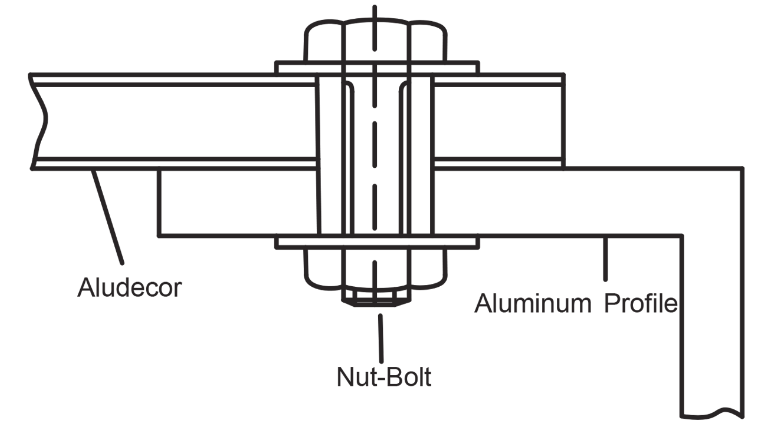

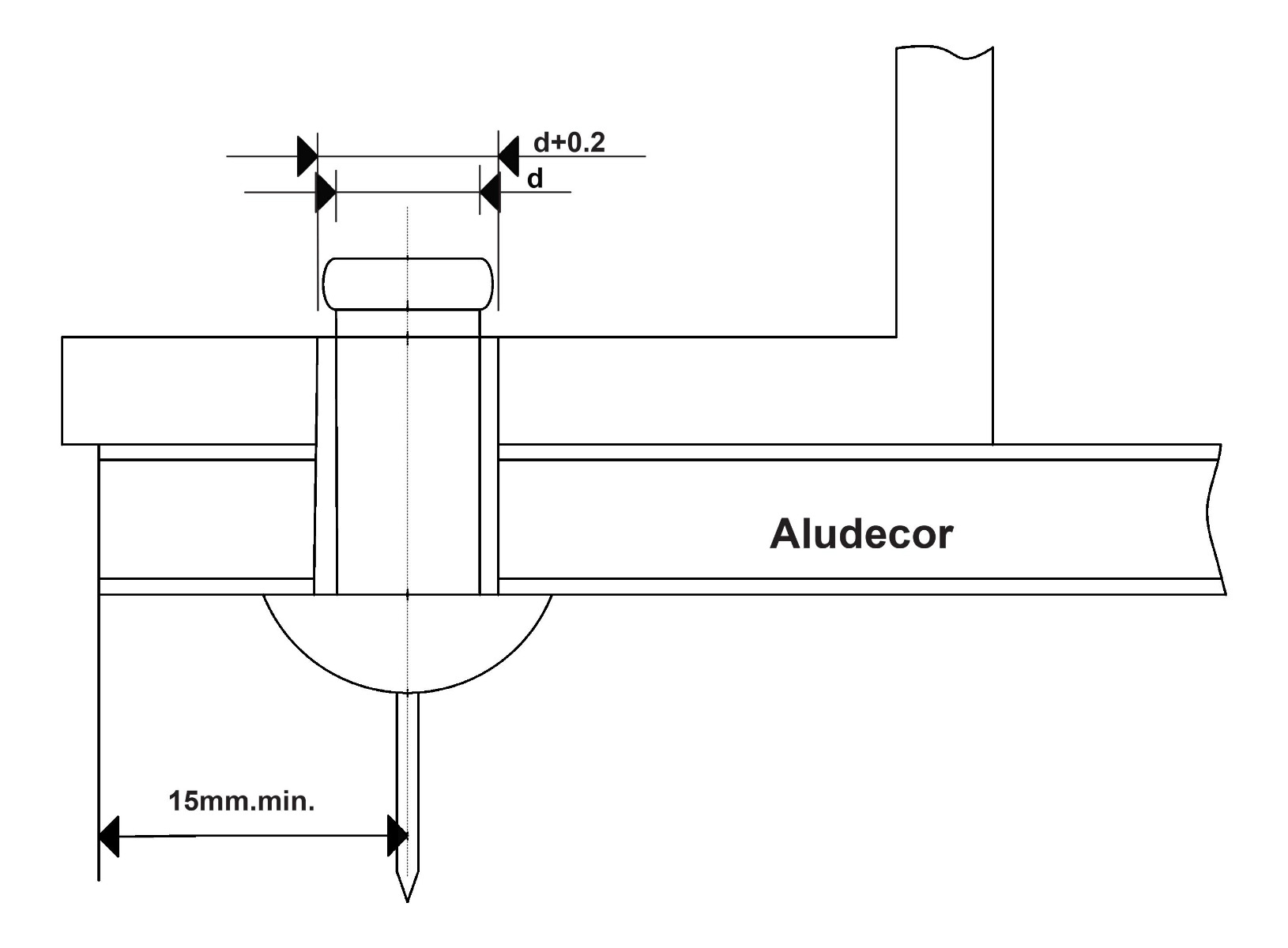

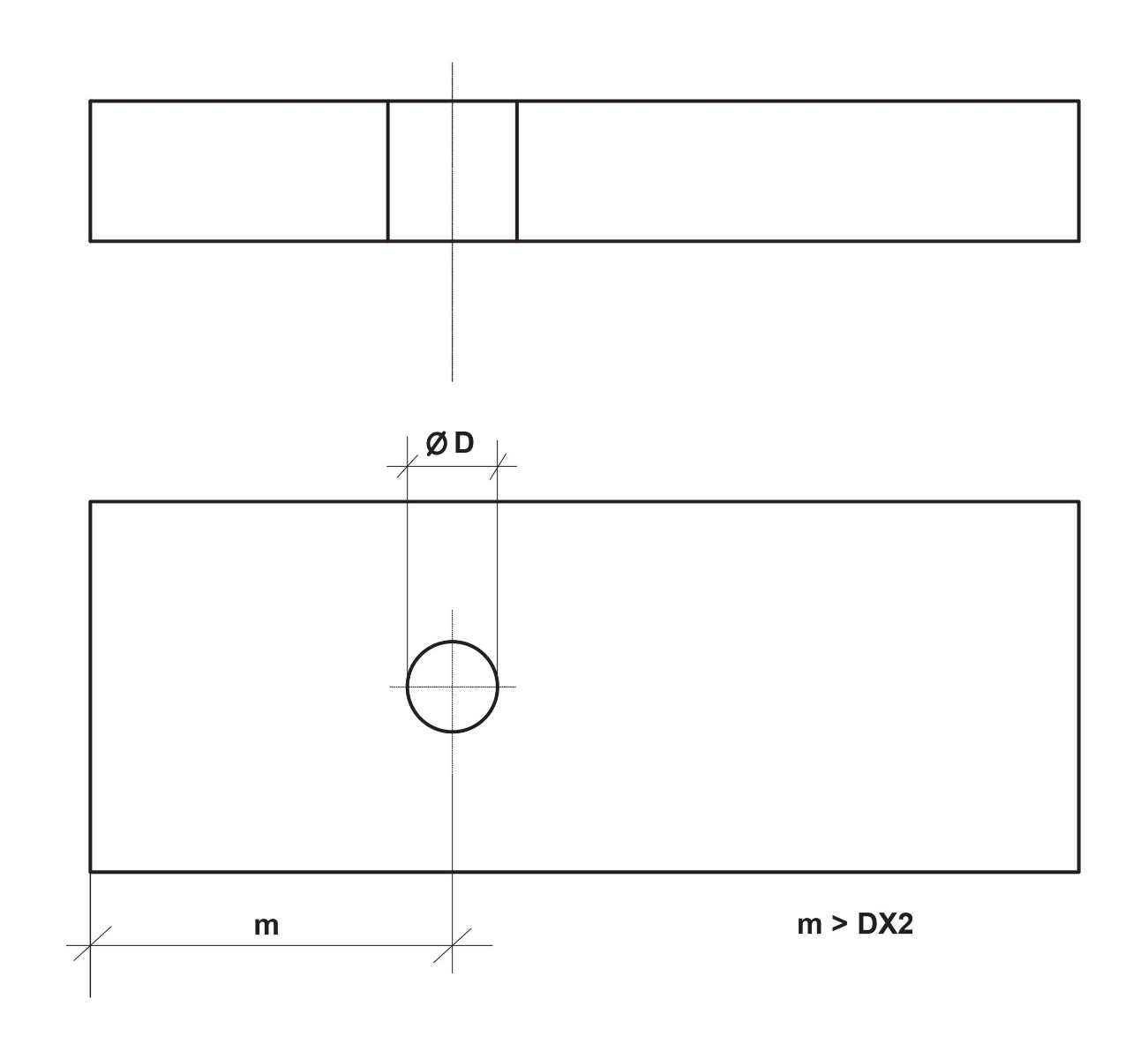

When working with Aludecor ACP boards, one must use aluminium blind rivets for junctions. Besides, stainless steel bolts and nuts must be used while fixing works must be progressed upon from the same direction.

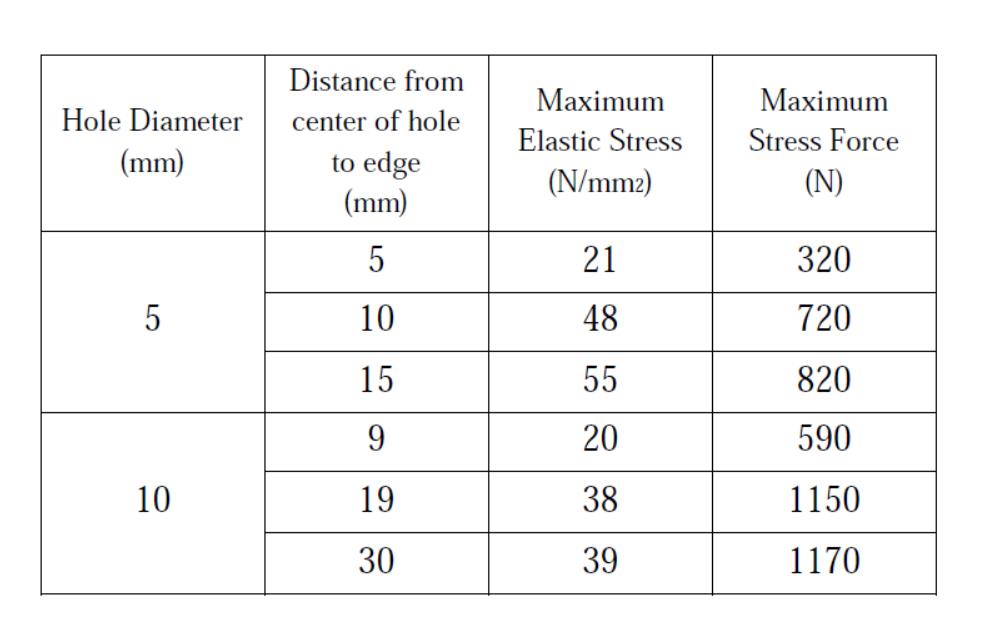

Fmax=σ x s x ø

Fmax : Stress Force (N)

σ : Elastic Stress (N/mm²)

s : ACP Panel Thickness (mm)

ø : Hole Diameter (mm)

Aludecor ACP board can be enhanced aesthetically by CNC cut designs. Use CNC cutters that are made especially for aluminium.

When it comes to choosing the right ACP sheets for your construction project, it's essential to factor in the overall cost, including the ACP sheet price with fitting. At Aludecor, we offer competitive pricing for our high-quality ACP sheets, and our Fabrication Guide provides a detailed breakdown of the pricing structure, including installation costs. Our team of experts ensures that the installation process is seamless and efficient, which helps minimize any additional expenses.

One of the key advantages of choosing Aludecor for your ACP sheet needs is our focus on affordability. We understand that ACP sheet price with fitting can be a major concern for builders, contractors, and designers. That's why we offer a range of ACP sheets that balance quality and price. Additionally, our ACP sheets are known for their durability, low maintenance, and longevity, which makes them a cost-effective option in the long run.

Look no further for high-quality ACP sheets with competitive ACP sheet price with fitting, Aludecor is the perfect choice for you. Our commitment to quality and affordability has made us a trusted brand in the construction industry

Sign In

Create New Account