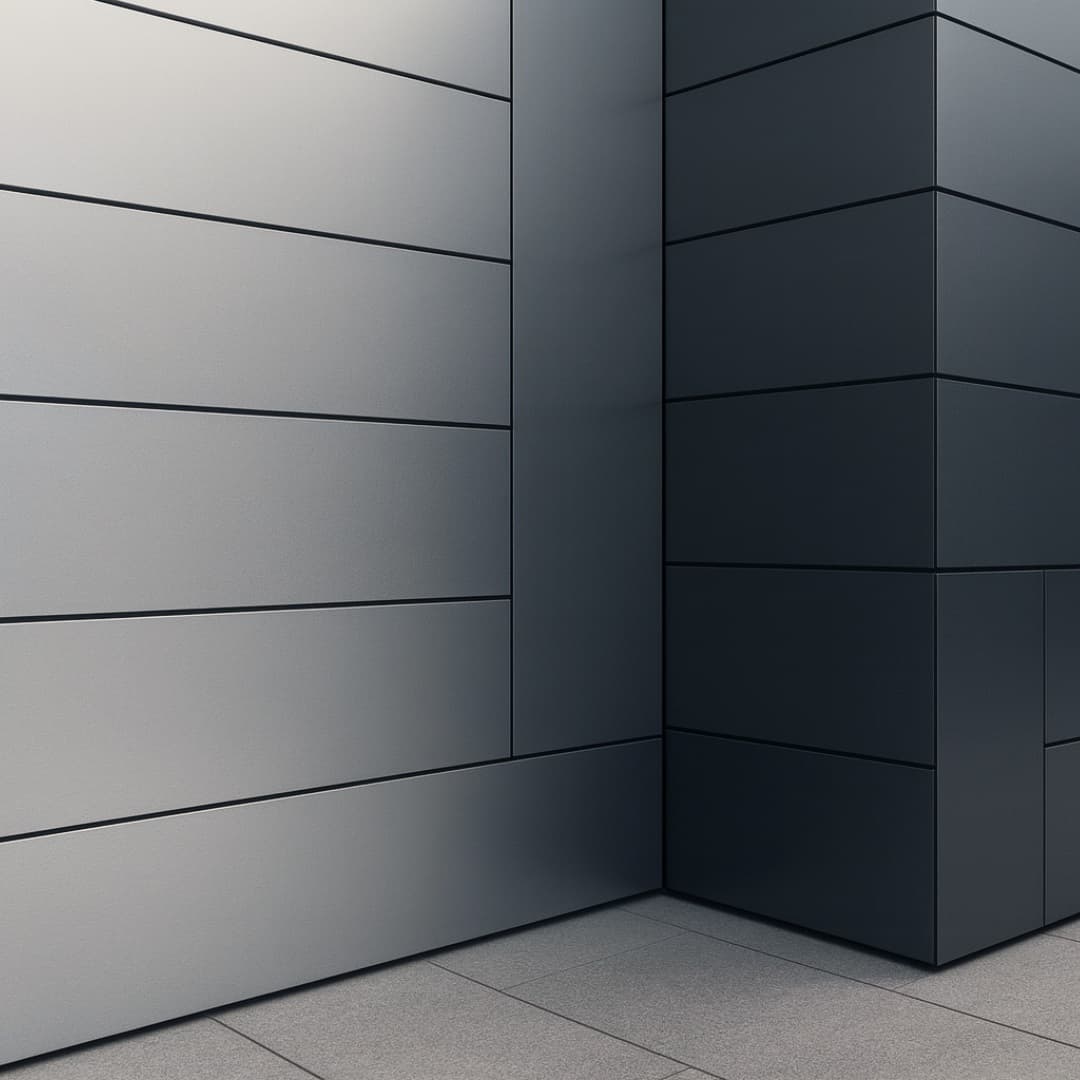

Solid Aluminium Sheets or panels are ideal for facades and having the ability to withstand extreme weather conditions & pollution. Solid aluminium panels are considered as non-combustible material i.e. FR Class-A1 certified according to DIN 13501.

Solid Aluminium Panels are widely used pre painted Aluminium sheets. They are used in façade cladding and solid frames for doors and windows. The main characteristics of Solid Aluminium Panels are:

Solid Aluminium Panels are weather resistant and corrosion resistant.

Solid Aluminium Panels are flexible and can be molded into any design & shape like arc, curved, round.

Very high quality of Aluminium is used for the same; these panels could have perforated designs on them.

It is light in weight (compared to other solid metal sheets of same thickness) & has good material strength.

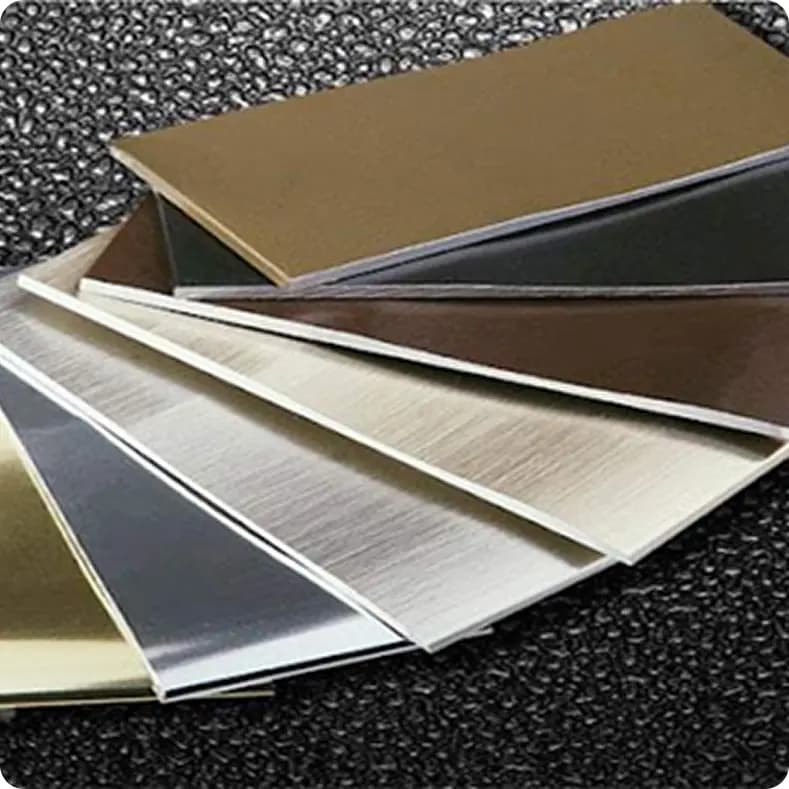

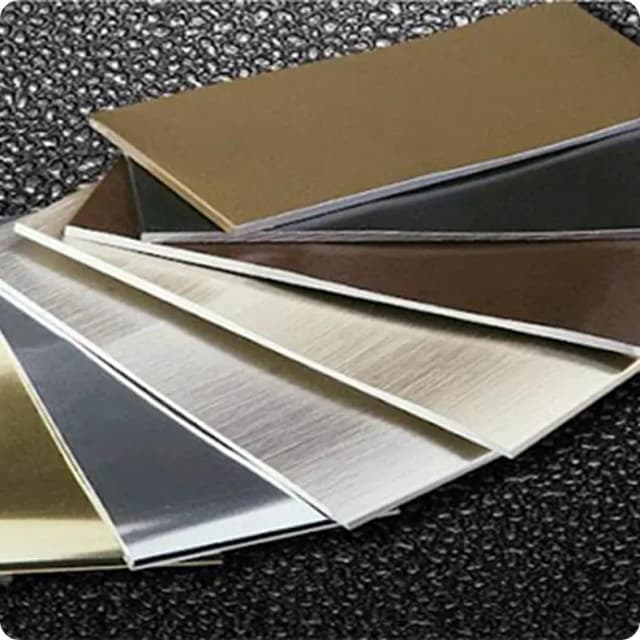

Finish longevity: PVDF/FEVE/SDP coil coatings or architectural powder coating; gloss/matte/metallic/texture options.

Lightweight, strong: Lower weight than steel at comparable thickness; good impact resistance and dent repairability.

Color breadth: Solids, metallics, special series (wood, stone, concrete effects), and custom matches.

The powder coating of Aluminium is done using special thermosetting resin based powder.

Finish longevity: PVDF/FEVE/SDP coil coatings or architectural powder coating; gloss/matte/metallic/texture options.

Non-combustible base metal: The material is fire resistant. FR Class-A1. Aluminum itself does not burn; project assemblies can achieve high Euroclass ratings (e.g., EN 13501-1 A1/A2 depending on coating/finish and test scope). Test reports available on request.

Design freedom: Fold, bend, roll, rout-and-return, punch, and CNC mill; tight radii and complex geometries possible.

Low maintenance: Solid Aluminium Panels are resistant to acids and alkalis. Smooth, non-porous surfaces clean quickly; graffiti-removal compatible finishes available.

All About Solid Aluminium Panels

- Panel Formats

- Applications of Solid Aluminum Panels

- Surface & Finishes

Solid Aluminium Sheets / Panels

- Coil-coated sheets: 50–0.80 mm (≈ 0.020–0.032 in) – ideal for soffits, liners, trims, signage backers.

- Made-to-Measure cassettes (M2M): 00–3.00 mm (≈ 0.040–0.118 in).

- Ready-to-Install cassettes (R2I): 00–3.00 mm (≈ 0.040–0.118 in) with concealed fixing options.

- Perforated panels (flat or R2I): 00–3.00 mm with standard or custom patterns.

- Curved/folded panels: 00–3.00 mm to suit arcs, radii, and complex geometries.

Solid aluminum sheets for eco-conscious facade cladding

| Sr. No. | Technical Properties | Standards | Solid Aluminium Panels | |

|---|---|---|---|---|

| 1 | Alloy Grad | EN 573-3 | AA3105 | AA5005 |

| 2 | Temper | EN 485-2 | H14 | H24 |

| 3 | Standard Thickness (mm) | EN 485-4 | 1.00 - 3.00 | 1.00 - 3.00 |

| 4 | Standard Widths (mm) | EN 485-4 | 500 - 1500 or Customized | 500 - 1500 or Customized |

| 5 | Standard Length (mm) | EN 485-4 | 1000 - 3660 or Customized | 1000 - 3660 or Customized |

| 6 | Panel Weight (Kg/m2) | 8.1 | 8.1 | |

| 7 | Tensile Strength | ASTM E8 | 140 - 185 | 130 - 175 |

| 8 | 0.2% Proof Stress | ASTM E8 | ≥ 110 | ≥ 110 |

| 9 | Elongation | ASTM E8 | A50 ≥ 5% | A50 ≥ 5% |

| 10 | Linear Thermal Expansion | EN 1999 1-1 | 2.4 mm/m at 100 °C temperature difference | 2.4 mm/m at 100 °C temperature difference |

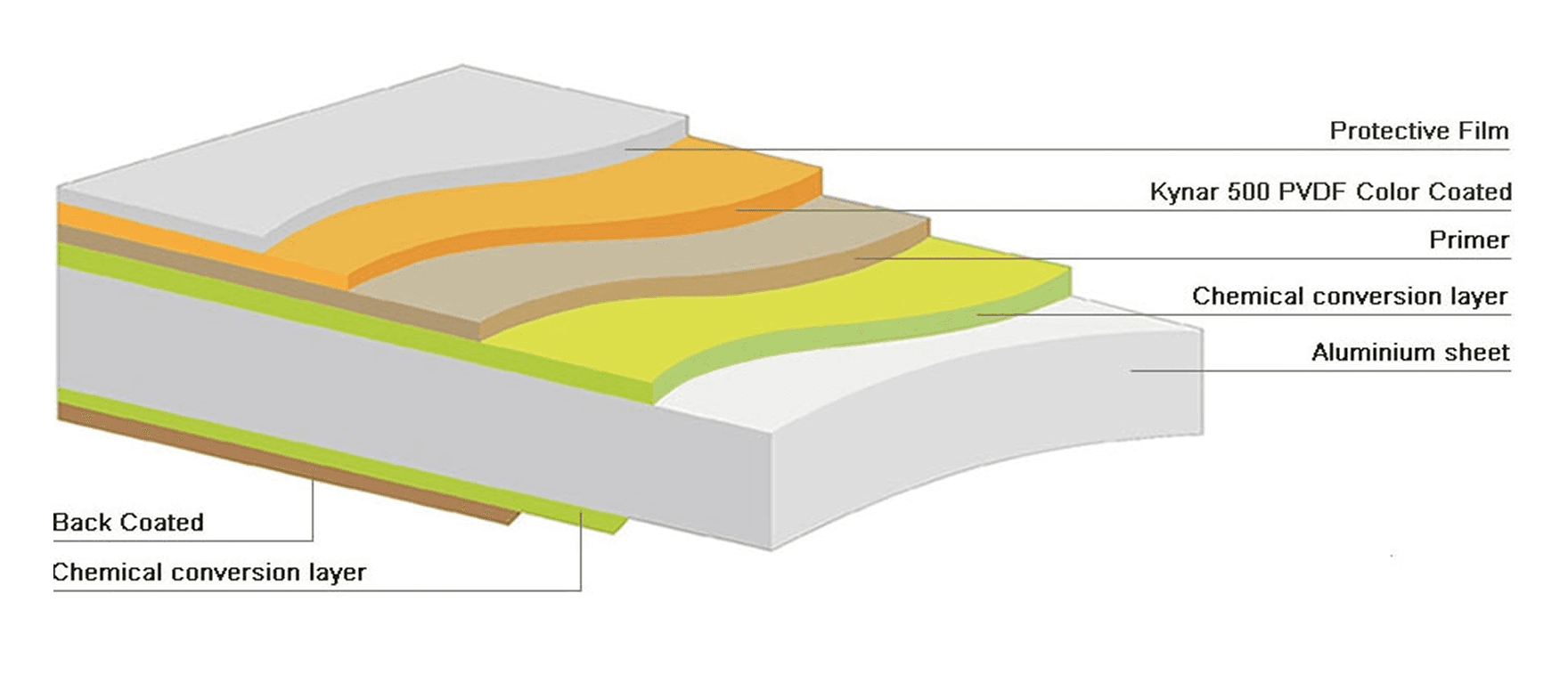

| 11 | Surface Coating | Fluoropolymer Paint Coatings | PVDF/FEVE | PVDF/FEVE |

| 12 | Gloss | ASTM D 523 | Depending on colour | Depending on colour |

| 13 | Coating Thickness (µ) | ASTM D 7091 | 20 – 30µ (for 2 Coat) 30 – 40µ (for 3 Coat) | 20 – 30µ (for 2 Coat) 30 – 40µ (for 3 Coat) |

| 14 | Fire Classification | EN 13501-1 | FR-A1 | FR-A1 |

You can choose from various thicknesses, sizes, colors, and finishes to meet your specific requirements. Our team of experts is ready to assist you in selecting the perfect sheet for your project.

Aludecorum is one of India’s only Non-Combustible Solid aluminium cladding panels purpose designed for use in new constructions and recladding applications.

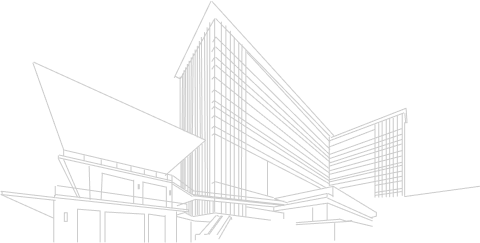

Developed and manufactured by Aludecor, Aludecorum is a solid aluminium panel which offers exceptional fire performance, dependable serviceability and a durable long-lasting PVDF finished face. It is a low maintenance solution to add high impact and striking features to create iconic landmarks. The elevated mechanical properties, outstanding surface flatness and simple fabrication mean Aludecorum is perfectly suited to cladding requirements within commercial, residential and high elevation developments.

Aludecorum is also an efficient, cost-effective method for transforming older structures – creative, contemporary new looks are easily achieved as Aludecorum is ideal for retro-fitting over existing facades. Aludecorum requires minimal maintenance and provides excellent long-term performance making it the first choice for all aluminium cladding projects.

Aludecor’s Solid Aluminium Panels are engineered to deliver strength, safety, and design flexibility for modern facades. Unlike composite materials, these panels are made from a single skin of high-quality aluminum, ensuring non-combustibility and compliance with stringent fire safety standards such as EN 13501-1 (A1/A2 assemblies achievable). Available in standard 3 mm thickness with options from 2 mm to 5 mm, the panels are produced in durable alloys like 3105 and 5005 with tempers H14 or H24, offering the perfect balance of tensile strength and formability.

The surface is finished with premium PVDF or FEVE coil coatings conforming to AAMA 2605, delivering long-term resistance to UV radiation, corrosion, and industrial pollutants. Panels maintain flatness and rigidity, making them ideal for large façade modules, soffits, and perforated designs. They are fabrication-friendly—easy to cut, fold, roll, rout, or perforate—enabling limitless architectural creativity.

Aludecor’s Solid Aluminium Panels are versatile, durable, and designed for a wide range of architectural and interior projects. Their non-combustible nature, excellent flatness, and long-lasting PVDF/FEVE finishes make them a preferred choice for modern construction and refurbishment works across the globe.

In exterior projects, Solid Aluminium Panels are widely used for curtain walls, rainscreen facades, soffits, and cladding systems, providing both fire safety and superior weather resistance. They are also ideal for building renovation and re-cladding of old structures, offering a fresh, modern look while improving performance.For interiors, these panels can be applied to ceilings, wall linings, balconies, and partition screens, creating sleek, low-maintenance surfaces that withstand heavy usage in public spaces. Their flexibility also makes them suitable for shopping malls, retail outlets, hotels, airports, subway stations, and universities, where both durability and design aesthetics are essential.

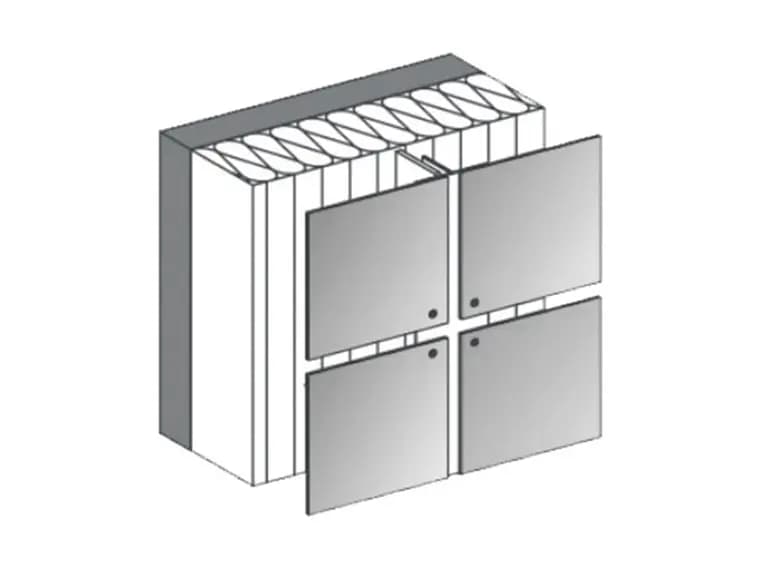

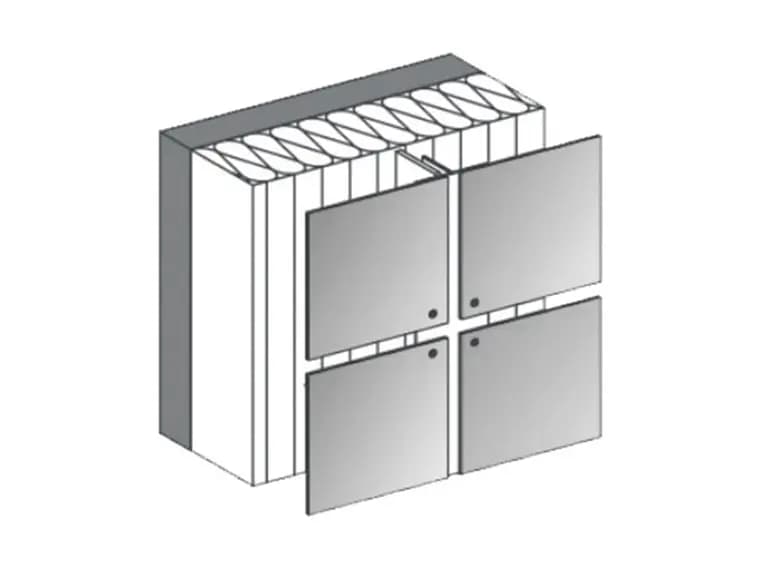

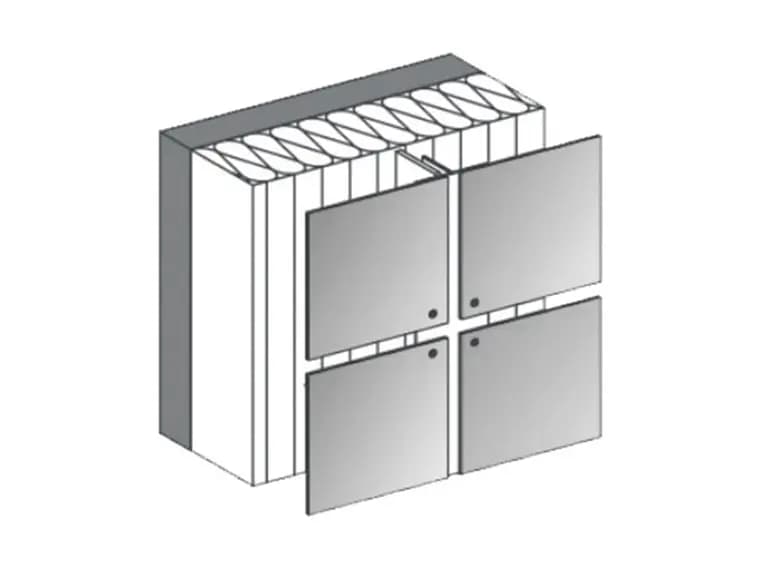

Solid Aluminium Panels can be installed using multiple fixing systems

| Width | ± 2.0 mm |

| Length | ± 4.0 mm |

| Thickness | ± 2% |

| Bow Maximum | 0.5% of the length and/or width |

| Squareness Maximum | 5.0 mm |

| Surface Defects | The surface shall not have any irregularities such as dents, scratches and other imperfections in accordance with our quality assurance |

Riveted Fixing: Cost-effective exposed-fastener system for quick installation of solid aluminum panels.

Hook-On Bolt System: Concealed fixing method that delivers seamless aesthetics and easy panel replacement.

Tray Panel System: Folded cassette design with hidden anchors, ensuring rigidity and a sleek façade finish.