At Aludecor, our mantra is simple yet uncompromising: Quality First, Purity First. In collaboration with NedZink, the world’s leading supplier of rolled titanium-zinc, we bring premium Zinc Solid Panels designed to transform facades and roofs with unmatched durability, aesthetics, and sustainability. Crafted from high-grade titanium-zinc with ≥99.995% purity, our panels meet and exceed global standards including EN 988, ASTM B69, and ISO 9001:2008 – ZN-1. These panels are not just cladding – they are a perfect fusion of beauty, functionality, and design flexibility, offering limitless possibilities for modern architectural expression.

Architectural Freedom Without Limits

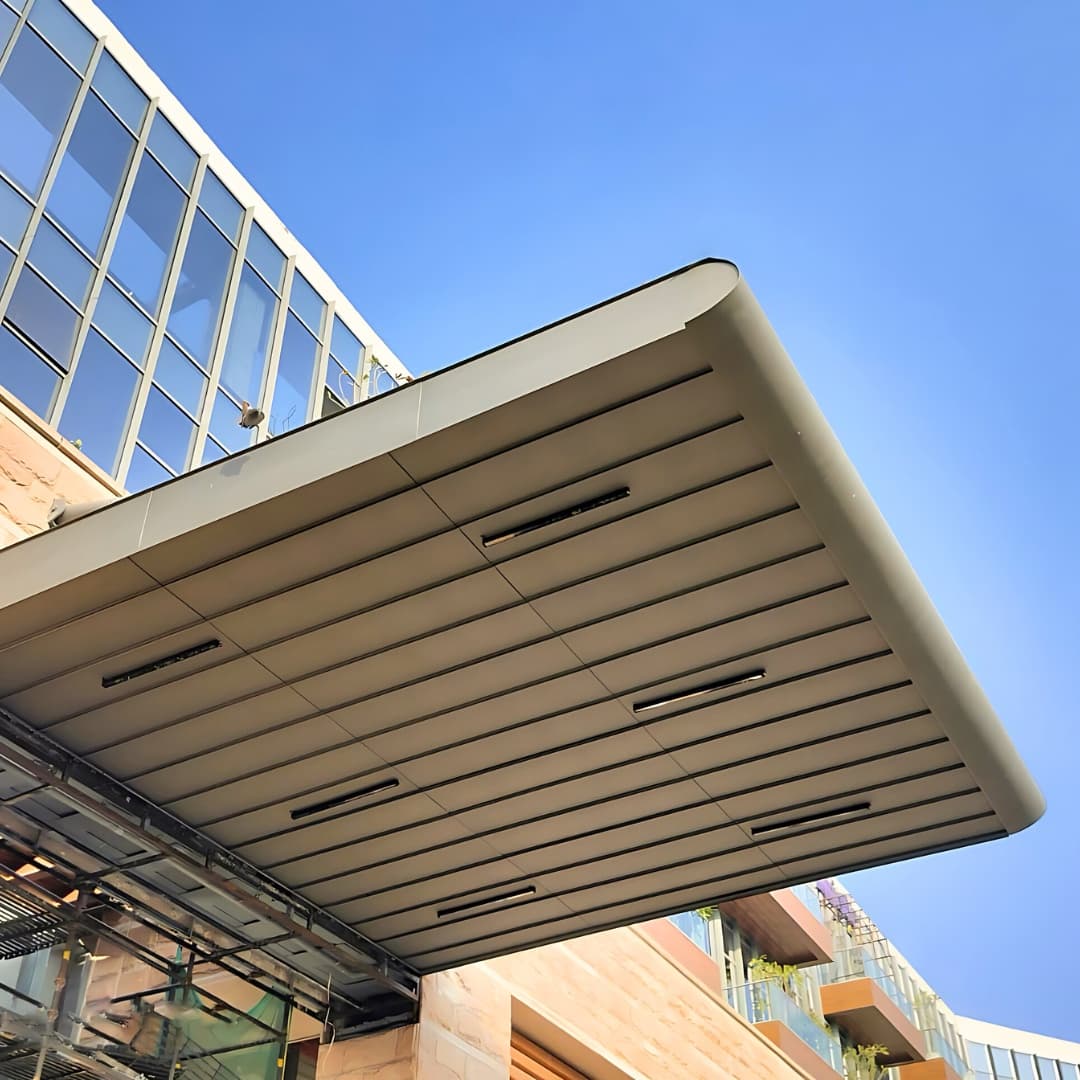

From sleek high-rise façades to intricate low-radius curves, Aludecor Zinc Solid Panels adapt to your vision. The material’s superior malleability allows bending, folding, and shaping into complex designs that traditional cladding materials cannot achieve. This design flexibility empowers architects to bring even the most ambitious concepts to life — whether for contemporary roofing, ventilated façades, or iconic public structures.

A Legacy of Zinc, Reinvented for the Future

Zinc has been used in construction for thousands of years, valued for its strength, workability, and natural patina. Aludecor’s partnership with NedZink blends this historic reliability with cutting-edge manufacturing, delivering panels with exceptional mechanical strength, creep resistance, and a proven lifespan in demanding environments.

Unmatched Durability and Sustainability

Our rolled titanium-zinc alloy, enhanced with copper for improved mechanical performance, has earned a solid reputation in global roofing and façade markets for over two centuries. The material naturally develops a self-protecting patina that resists corrosion, reduces maintenance, and ensures aesthetic stability over time. Fully recyclable, Aludecor Zinc Solid Panels align perfectly with green building certifications and eco-friendly construction goals.

Quality Assurance & Warranty

Every panel is produced under rigorous quality control, with regular inspections by independent agencies. Should any issue arise, Aludecor’s direct warranty support ensures quick, professional resolution – giving architects, builders, and property owners complete peace of mind. With Aludecor Zinc Solid Panels, Indian architecture gains access to world-class titanium-zinc solutions – setting new benchmarks for façade innovation, durability, and sustainable design.

Aludecor Zinc Solid Panel are Beautiful and Long-Lasting

Natural, environmentally responsible cladding material with 100% recyclable qualities.

Due to the Zinc Carbonate Layer, Aludecor Zinc Solid Panel have a shelf life of more than 100 years.

Easy to Install and Maintain Aludecor Zinc Solid Panel.

After installation, Aludecor Zinc Solid Panel don't stain surrounding surfaces.

Perfect malleability makes Aludecor Zinc Solid Panels suitable for any surface, whether curved or bent.

For better environmental aspects, Aludecor Zinc Solid Panels Produce Clean Rainwater Runoff.

Even after more than a century of use, the market value of Aludecor Zinc Solid Panels remains unchanged.

100% Green Certification for Aludecor Zinc Solid Panel.

The zinc solid panel lasts for a very long time as well. ZSP is one of the best modern cladding materials due to the natural attraction of the zinc as well as its flatness, strength, simplicity in manufacture, and affordability.

The sustainability of zinc roofing is a huge fact impacting upon greener & healthier building society. However, it is important to keep in mind that zinc roof sheets use less energy to manufacture than many other metal systems simply because it has a lower melting temperature, which makes it simpler to create with less energy. The material used to make the roof is entirely recyclable after it has served its purpose or after the structure is demolished.

Here at Aludecor Zinc Roofing, we frequently employ zinc, a fantastic metal roofing material. Metal roofing sheets is widely employed worldwide, especially for commercial structures and historic roof renovations. Galvanized steel, copper, aluminium, zinc, and stainless steel are the most popular materials used to make metal roofs. An effective design and installation can extend the lifespan of a zinc roof to more than 100 years. For large and small roof surfaces, zinc is the best material for roof covering. You can select from several systems for a zinc roof, including the standing seam system, roll cap system, and lozenge system. The choice of a certain system is influenced by the various ways the systems look. On the other hand, all cladding must be vented, which means there must be a place for ventilation behind the material. Without a ventilation space, fluctuations in zinc temperature can lead to moisture behind the cladding that cannot escape, increasing the danger of corrosion.

For roofs with an angle of inclination starting at 18 degrees, the lozenge method is appropriate. On top of a wooden substructure, the zinc roofing sheets are arranged in a diamond. Lozenges, commonly referred to as “zinc slates,” are the building blocks of the lozenge system. These relatively small bent zinc plates interlock with a hook connected to provide the impression of a regular slate roof. The lower melting point of zinc makes it more energy-efficient to produce than other metal roofing materials. The energy needed to transform the raw material into a proper form is reduced. Moreover, UV radiation cannot destroy zinc, making it weatherproof. The direction of the metal’s grain must always be followed when cleaning zinc. It is not advised to use pressure washers. Applying a minimal amount of mineral oil can help to enhance cleaning with detergent. Any application of mineral oil must wait until the zinc is dry.

Discover why titanium-zinc roofing is the preferred choice

Century-long lifespan (75–100 years): Titanium-zinc develops a natural, self-protecting patina that resists corrosion and keeps roofs performing for decades.

Near-zero maintenance: No repainting required—just periodic inspection and cleaning. The patina helps mask minor scratches over time.

Zinc is versatile and simple to work with, so it may be used to cover a variety of roof shapes. Zinc can be used to cover small flat and sloping roofs. Many options are available when using zinc as a roofing material, including the ability to create curved roofs.

Works on small flat and sloped roofs: Ideal for standing seam, shingles/flat-lock, and interlocking systems across small flat areas and low-to-medium slopes.

The capacity to develop a protective patina that stops the zinc from oxidising gives zinc its inherent longevity as a roofing, roof drainage, and exterior cladding material. Additionally, over the course of the material’s life, the patina allows for little to no maintenance requirements. The façade panel system made from the zinc cladding skin has the best mechanical and physical properties since it is made of rolled zinc alloyed with copper and titanium. Of all the cladding systems on the market, the material possesses some of the best mechanical and creep resistance. As zinc external façade cladding, titanium zinc is ideal. Zinc offers a variety of façade methods, each with a distinctive appearance. The cassette and reveal panel systems are also excellent choices for zinc façade cladding, in addition to the conventional zinc roof methods like the standing seam and lozenge system.

Zinc is 100% recyclable, providing the structure with a contemporary appearance.

Use distinctive zinc cladding to draw attention to specific places and impart a sense of exclusivity.

Zinc is simple to work with. Therefore, there are countless design options! Many different types of facades are covered in zinc.

A zinc façade has a long lifespan and requires no maintenance.