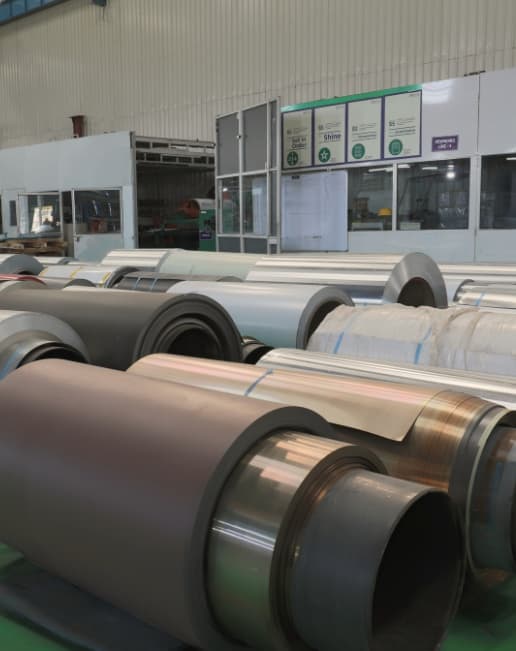

Aludecor is a leading manufacturer of Coated Aluminium Coils situated at Haridwar – Uttarakhand, India. Our Coil Coating lines produce the best quality Pre-coated Aluminium Coils, in complete accordance with global industry quality standards. In order to cater varied demands of clients, these superior quality products can also be also customised in various sizes and other related specifications.

Aludecor’s Pre-coated Aluminium Coils are produced by adding paint coatings to mill finish aluminium coils on a continuous basis with a process called ‘Coil Coating’. Coil coating is a highly efficient means of coating aluminium before the fabrication of finished components, providing a high-quality, uniform and reproducible surface finish. Aludecor has performed a total of 30 tests to analyse the quality of Pre-Coated Aluminium Coils. Our regular quality tests ensure compliance with AAMA, ECCA, ASTM, ISO, EN, and DIN standards.

Unmatched colour consistency to deliver durable, lightweight, and sustainable solutions

Color-coated coils that deliver durable finishes, consistent gloss, and lower lifetime cost

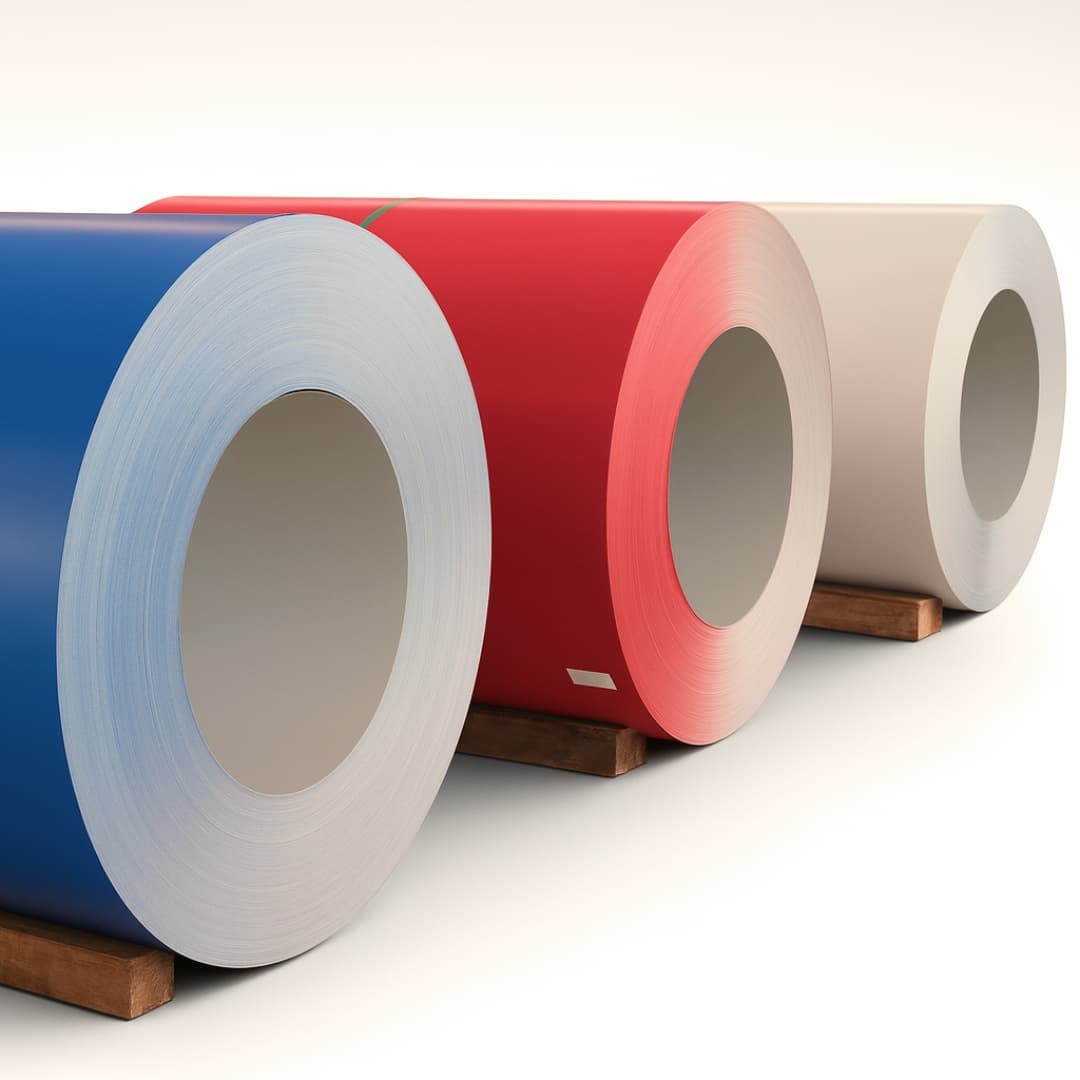

Vivid, Long-Lasting Colour

Aludecor’s PVDF and high-durability polyester (PE) systems provide rich, uniform colour with strong resistance to UV, corrosion, solvents, and severe weather. Colour and gloss retention remain stable for years, with warranty coverage up to 10-15 years depending on system and location.

Cost-Effective Over the Lifecycle

While the initial price of a pre-painted coil can be higher than some cladding options, total cost of ownership drops thanks to superior durability, low maintenance, and faster installation. Energy-reflective colours can further help reduce cooling loads, improving operating costs over time.

Unmatched Flatness and Gloss Retention

Precision coil-coating and process control deliver excellent flatness and coil-to-coil consistency, supporting tight fabrication tolerances for cassettes, panels, and press-formed parts. The controlled film build helps maintain gloss uniformity and colour consistency across large elevations.

Anti-microbial & Anti-insect coating

For environments that demand cleaner surfaces, optional antimicrobial coatings inhibit the growth of bacteria, mould, and fungi-ideal for HVAC fins/ducting, healthcare, and food facilities. Anti-insect coatings help repel or reduce adherence on outdoor/ industrial surfaces. These specialised finishes enhance functionality and longevity when projects require added protection.

Factory-finished, color-coated coils are used wherever fabricated parts need a premium, uniform painted surface-spanning building façades, roofing, signage, HVAC, transportation and OEM enclosures.

Name of Testings

- Paint Viscosity

- Paint Density or Specific Gravity

- Paint's Particle Size

- NVM (Solid Content)

- Visual Shade Match

- Color Difference

- Gloss@60°C

- DFT

- Pencil Hardness

- T-Bend test

- Cross Hatch Adhesion test

- Cupping Test

- Reverse Impact test

- MEK Test

- Scratch Hardness

- Acid Test(HCl)

- Alkali Test(NaOH)

- Boiling water adhesion test

- Chloroform Test

- Pointage of Parco (Pre-Degreasing)

- Pointage of Ridolene (Degreasing)

- PH of Water

- T-Bend Test

- Coil Thickness

- DFT of Primer

- DFT of Top Coat

- WFT

- QUV Test (Accelerated Weathering Test)

- SST (Salt Spray Test)

- Humidity Resistance Test

Equipment Used

B4 Cup/Ford Cup

Test Standard/Method

ASTM D 5125

Specify pre-coated aluminum coils with confidence

| Aluminium Alloy | AA1100, AA3105 & AA5005 are used for its strength and durability. |

| Coating Technology | We have 3 Coil Coating Lines:

Total Installed Capacity – 22000 MT per Annum |

| Technology | High automation level of the new Coating Lines are applied in technological processes which are crucially important for final product quality:

|

| Thickness and Width Options | Aludecor provides options that are available for different project needs.

|

- 1100

- 3105

- 5005

Temper

H42, H44, H46, H48 (after Coil Coating)

Remarks

★Temper H14, H16, H18, H22, H24, H26 for base material are provided as per the client’s request and mutually agreed.