Engineered for zero flame spread, no smoke, and maximum protection — FireWall FR A2 ACP sheets by Aludecor, India’s largest ACP sheet manufacturer, redefine fire safety for modern architecture. Tested across international standards, FireWall panels offer unbeatable protection for high-rises, hospitals, metro stations, airports, and other critical infrastructure.

Fire safety begins long before the first spark. Many traditional ACP sheets use polyethylene cores, which can act as fuel during fire incidents — leading to flame spread and toxic smoke. Aludecor FireWall A2, however, is engineered with a 90% mineral-based inorganic core, ensuring no flame propagation and minimal smoke generation.

As India’s most advanced fire-retardant ACP sheet, FireWall combines superior European safety certification (EOTA Ref.) with in-house manufacturing precision. It is designed for compliance with national fire safety codes and provides unmatched reliability in sensitive structures like schools, airports, and residential towers. Choosing the right fire-resistant ACP sheet isn’t just a specification — it’s a commitment to saving lives and protecting property.

A next-generation Fire-Retardant ACP Sheet engineered for zero flame spread, no smoke, and unmatched safety.

FireWall A2 is the highest global classification for fire-resistant ACP sheets — A2-s1,d0 under EN 13501-1. It is non-combustible, meaning it neither contributes to the fire nor emits smoke or flaming droplets. Designed for crowded or high-rise environments, it ensures complete compliance with building regulations for structures above 15 meters.

FireWall A2 at a Glance:

- Globally recognized A2-grade performance

- Zero flame spread | Zero smoke release

- Highest level of Fire-safety with European ETA certification for FR-A2 FR-B

- Ideal for vertical, public, and high-occupancy buildings

Our FR A2 ACP sheets are engineered to completely stop flame propagation.

Designed for minimal smoke emission (s1 rating) under EN 13501-1 standards.

No dripping, no molten residue — just complete fire containment.

At the heart of every FireWall fire-retardant ACP sheet lies advanced chemistry. Aludecor uses Magnesium Hydroxide (MDH) — a halogen-free, non-toxic mineral that outperforms traditional fillers like Aluminium Trihydrate (ATH).

FireWall A2 is 90% halogen-free, inorganic material that produces water vapour when it heats up. FireWall has more than 71% mineral content. Both do not produce toxic gases like halogenated materials.

Magnesium hydroxide (MDH) is the non-halogenated material that is mixed with PE to form the core of Aludecor’s FR products. MDH has a better fire-resistance performance than aluminium trihydrate (ATH), the other non-halogenated material, owing to higher decomposition temperature. Furthermore, MDH is more environment-friendly than other similar materials. MDH delays the PE transformation from solid to plastic (the point of ignition) up to 360°C, by releasing water molecules and bringing down the temperature continuously.

Why MDH is superior:

MDH releases water molecules when exposed to heat, reducing core temperature and delaying ignition. This unique reaction creates a self-cooling, self-extinguishing barrier — ensuring that FireWall A2 remains stable and smoke-free even under extreme fire exposure.

| Material | Fire Behavior | Decomposition Temp | Core Safety Level |

|---|---|---|---|

| MDH (FireWall A2) | Water release → flame delay | 310–360°C | ✅ A2 grade |

| ATH (Most brands) | Lower decomposition | 190–240°C | ⚠️ Lower FR Material |

| PE (Standard ACP) | Acts as flame fuel | 90–110°C | ❌ Dangerous |

Ensures zero toxic emissions and minimal smoke for occupant safety.

High resistance to ignition and smoke ensures operational safety in enclosed spaces.

Meets all fire compliance requirements for towers and skyscrapers.

Adds protection without compromising design or finish quality.

Certified and compliant with national and international fire codes.

Tested to Perform. Proven to Protect.

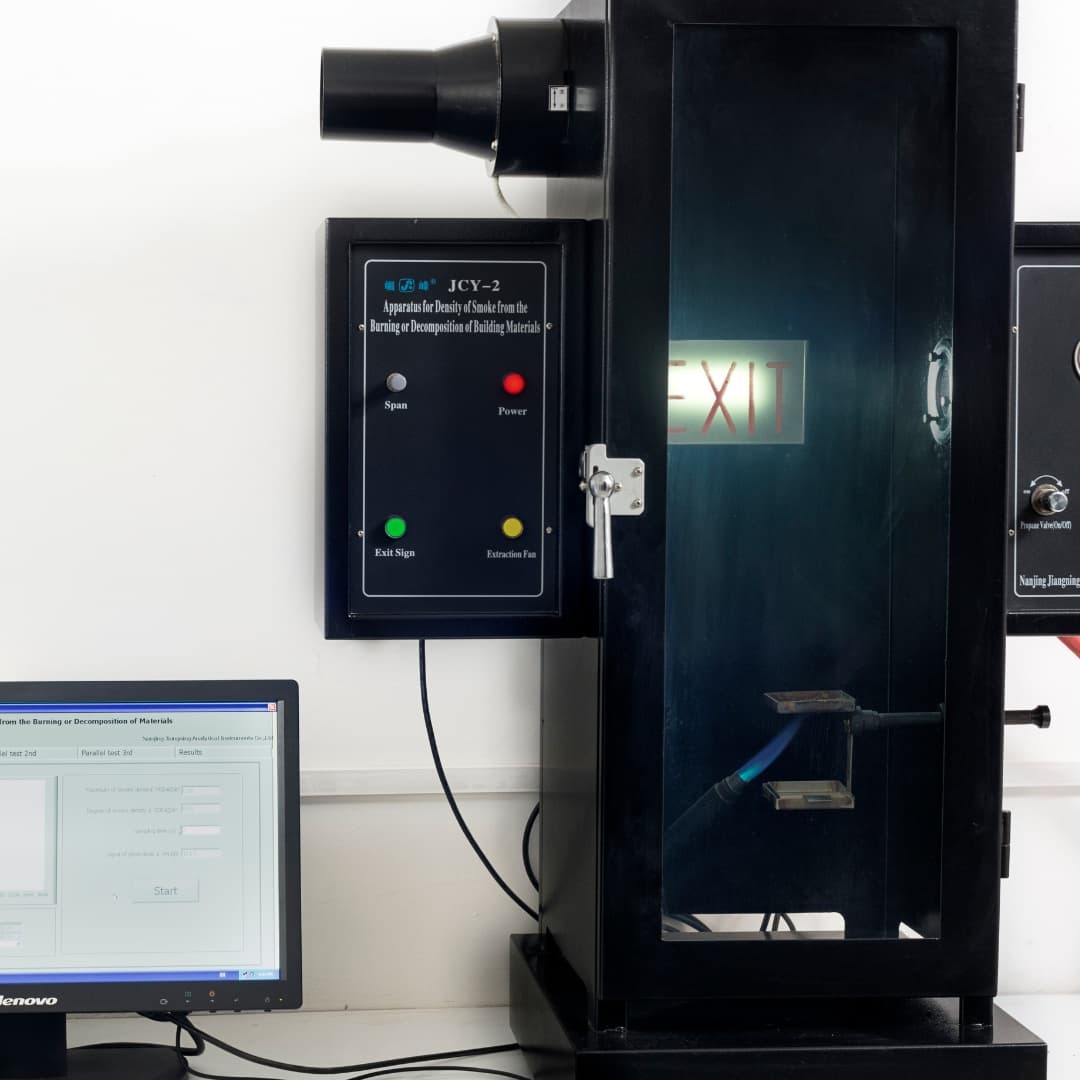

With NABL accreditation, Aludecor’s testing facilities meet ISO/IEC 17025 international standards, ensuring consistent accuracy in fire, mechanical, and chemical performance evaluations. This boosts the credibility of FireWall’s A2-s1,d0 classification, verified under global quality frameworks.

- No ignition up to 360°C

- No flaming droplets

- Zero toxic smoke

Determines whether the ACP sheet ignites when exposed to direct flame. FireWall A2 achieves zero ignition, ensuring complete non-combustibility.

Evaluates the material’s ability to resist burning under extreme temperatures. FireWall’s 90% mineral core guarantees no flame spread or heat release.

Measures the minimum oxygen concentration needed for combustion. FireWall FR A2 ACP has a high LOI value, meaning it cannot sustain fire in normal air conditions.

Assesses how much smoke is produced when the ACP sheet is exposed to fire. FireWall A2 records minimal smoke emission (s1 rating), ensuring clear visibility and safer evacuation.

Measures the total heat released during combustion. FireWall’s mineral core produces negligible heat output, confirming its non-combustible and fire-resistant performance.

Evaluates the bond strength between aluminum skins and the core. FireWall A2 ACP sheets maintain exceptional lamination integrity, even after extreme heat exposure.

Every batch of FireWall A2 undergoes multi-stage testing, including full-scale in-house trial production using our Baby Line ACP test bed. Also, highlight the 205 tests performed as part of our stringent quality measure.

What Our Clients Say