What can we help you with?

-

What is ACP?

ACP stands for Aluminium Composite Panel.

-

What is LDPE?

LDPE stands for Low Density Polyethylene. It is used as a core of Aluminium composite Panels.

-

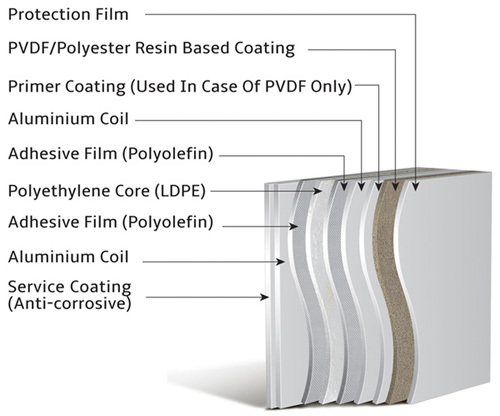

What are the components of ACP?

-

What are the various thicknesses in which ACP is available?

It is available in 4mm, 3mm and 1.5mm. 5mm and 6mm are available on request.

-

What is the size of ACP?

The width of Aludecor ACP is 1220 mm and length can be up to 6100 mm. Customized width of 965 mm is also available on request.

-

What is the thickness of paint on Aludecor ACP?

The thickness of the paint varies with the type of paint used:

- Polyester: 15-18µ (µ-micron)

- PVDF: 25-28µ, goes up to 30-35µ when given the third coat

- SDP: 25-28µ

-

From where do we source Aluminium Alloy? And who are our PVDF paint suppliers?

We source Aluminium Alloy from Hindalco, and PVDF paint from PPG, AkzoNobel, Berger Becker and Nippon

-

Which adhesive Film is used for bonding Aluminium with PE – Core?

Dupont Adhesive of Bynel series is used as an Adhesive Film.

-

What are the various tolerances of ACP?

The various dimensional tolerances of aluminium composite panels are as follows:

- Width - +/- 2.0mm

- Length - +/- 4.0mm

- Thickness +/- 0.2mm

- Bow maximum 0.5% of the length/width

- Squareness maximum 5.0mm.

-

What is the use of ACP in construction?

ACP as a product is used to enhance the aesthetics of a building. Its purpose is to give a well-defined, smart and a modern look.

-

Are aluminium composite panels Fire Resistant?

Aluminium composite panels are Fire resistant depending on the type of core material being used. Generally Mg(OH)2 is added as a non-combustible material.

-

What are the fire classifications in your product?

Aludecor has taken EN 13501-1 for flammability and reaction to fire, for resistance to fire on the complete system Aludecor has 2 hours ASTM E119 rating. These ratings are in comparison to BS 476, ASTM E84, NFPA, DIN 4102 etc.

-

What are the grades of aluminium used in manufacturing ACP?

- AA 1100/AA 3003: The alloy of this grade is a manganese alloy which has a minimum tensile strength of 120 N/mm2 and to be used for buildings below 10 meters.

- AA 3005/ AA3105: the alloy of this grade is a magnesium and manganese alloy which has a minimum tensile strength of 150 N/mm2. This is to be used for external façade solutions as magnesium decreases the chances of oxidation of aluminium and the tensile strength enables it to handle wind loads of 2.25 KPa easily.

- AA 5005: this alloy has the magnesium content nearing to 1% which is required in coastal regions for not letting the aluminium oxidize and paint to sustain high salty moisture content. Also, it has the minimum tensile strength of 150 N/mm2 which enables it to handle wind loads of 2.25 KPa.

-

What is tensile strength of metal and how it is expressed in units?

Tensile strength of the material is defined as strength required to resist the tensile forces acting on any material. It is expressed as Force per unit area. Tensile strength is expressed as N/mm2. When load is applied on a body, the body experiences compression and this generates an equal resisting force to regain its shape and this is known as Tension or Tensile strength

-

What is flexural strength?

Flexure means bending or bending strength of material. This is again calculated using bending strength formula.

-

What does ASTM stand for?

ASTM stands for American Society for Testing Material.

-

Which types of coatings are used in coating aluminium composite panels?

There are 5 types of coatings used:

- PVDF

- Lumiflon

- SDP (Super Durable Polyester)

- HDP (High-Density Polyester) Polyester

-

Which standard is followed in coating of Aluminium Coil for ACP?

AAMA 2620/2605 is followed. AAMA stands for American Architectural Manufacturers Associations.

-

What standard is used for measuring coating properties?

For measuring the coating properties AAMA 2605 is used for 10 years warranty, AAMA 2604 for 5 years warranty and AAMA 2603 for interiors

-

What is PVDF and what are its properties?

PVDF stands for Polyvinylidene Fluoride. It is a resin added to paints to increase its UV – resistant properties. This happens due to the C-F electrovalent bond

-

What is the difference between PVDF and Polyester?

- PVDF has a better weather resistance.

- PVDF has a higher flexibility as compared to polyester

- PVDF paint is of higher quality

- The durability of PVDF is higher

- PVDF comes with 10 years warranty

-

Is ACP scratch proof, especially interiors?

It has a scratch resistance of up to 4H.

-

How does the performance of paints differ with thickness?

The performance of paint increases with an increased thickness under a stipulated range set by AAMA. Two coats PVDF has a durability of 10 years and by increasing it to three coats the durability increases by 5 to 10 years.

-

Does weathering of paint depend on coil thickness?

No, the paint weathering has nothing to do with the sub-surface.

-

Why does the paint peel off from ACP?

The paint of the ACP will peel off in case of the following reasons:

- Improper cleaning

- Incorrect Routing

- Contamination of coil

- Inappropriate cutting

-

Why is the life of metallic colours lesser than solid colours?

Metallic colours obtain their gloss from organic pigments. These pigments have higher quantity of polyester contents compared to PVDF which provides the gloss, however, it reduces the life of the paint when used in the exterior. This is the reason why metallic colours have lesser life than solid colours. They lose their gloss much early than solid colours. This is in accordance to AAMA 2605 which states that in 10 years gloss remaining should be 50% of the original

Sign In

Create New Account