Overview: Behind the Layers of Aludecor ACP Fabrication

ACP Fabrication Guide: your definitive resource for mastering Aluminium Composite Panel fabrication with precision, durability, and style. Born from decades of R&D, Aludecor’s guide demystifies the chemical, physical, and mechanical properties of ACP / MCP materials and reveals why our panels are trusted across facades, interiors, signage, and architectural landmarks.

Purpose of the Guide

Understand exact fabrication techniques, from saw‑cutting, grooving, folding, to rout & return systems, that deliver clean edges, flush corners, and flawless installations. Learn how to choose the right methods, tools, and tolerances for every application, whether urban high‑rise, coastal building, or commercial display. Ensure your installations maximize durability, fire safety, finish retention, and structural integrity so your projects perform over time and under strain.

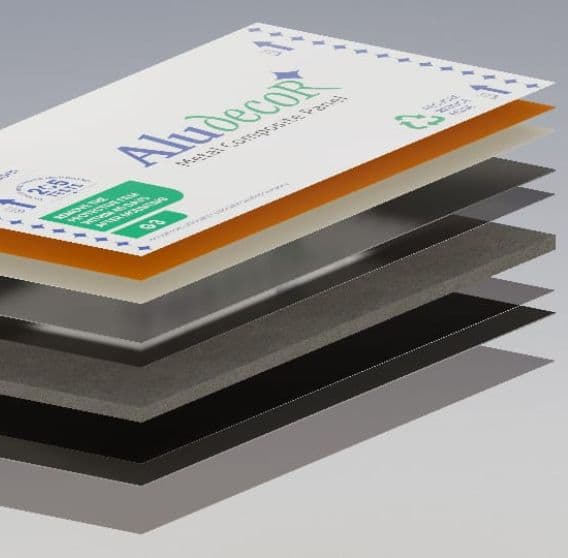

Know What Makes ACP Sheets Stand Out

Aluminium Composite Panels (ACP) consist of two aluminium sheets bonded to a polyethylene or fire-retardant mineral core. The outer surfaces are coated with PVDF or Polyester paint, providing excellent UV resistance, weather protection, and corrosion resistance. This composition makes ACP lightweight, durable, and cost-effective, ideal for contemporary architectural needs.

Aluminium Composite Panels (ACP) offer a combination of strength, flexibility, and durability. Fire-retardant variants enhance safety, while PVDF coatings ensure high UV and weather resistance. ACP is lightweight, rigid, easy to install, and customizable in a variety of shapes and colors. It requires minimal maintenance and is fully recyclable, making it an eco-friendly solution for facades, cladding, and interior applications.

Aluminium Composite Panels (ACP) are suitable for exterior facades, cladding, and roofing, providing design flexibility and structural durability. Indoors, they are used for walls, ceilings, and furniture. ACP is also widely used in signage, branding, canopies, and louvers, making it a preferred material for residential, commercial, and industrial projects across India and global markets.

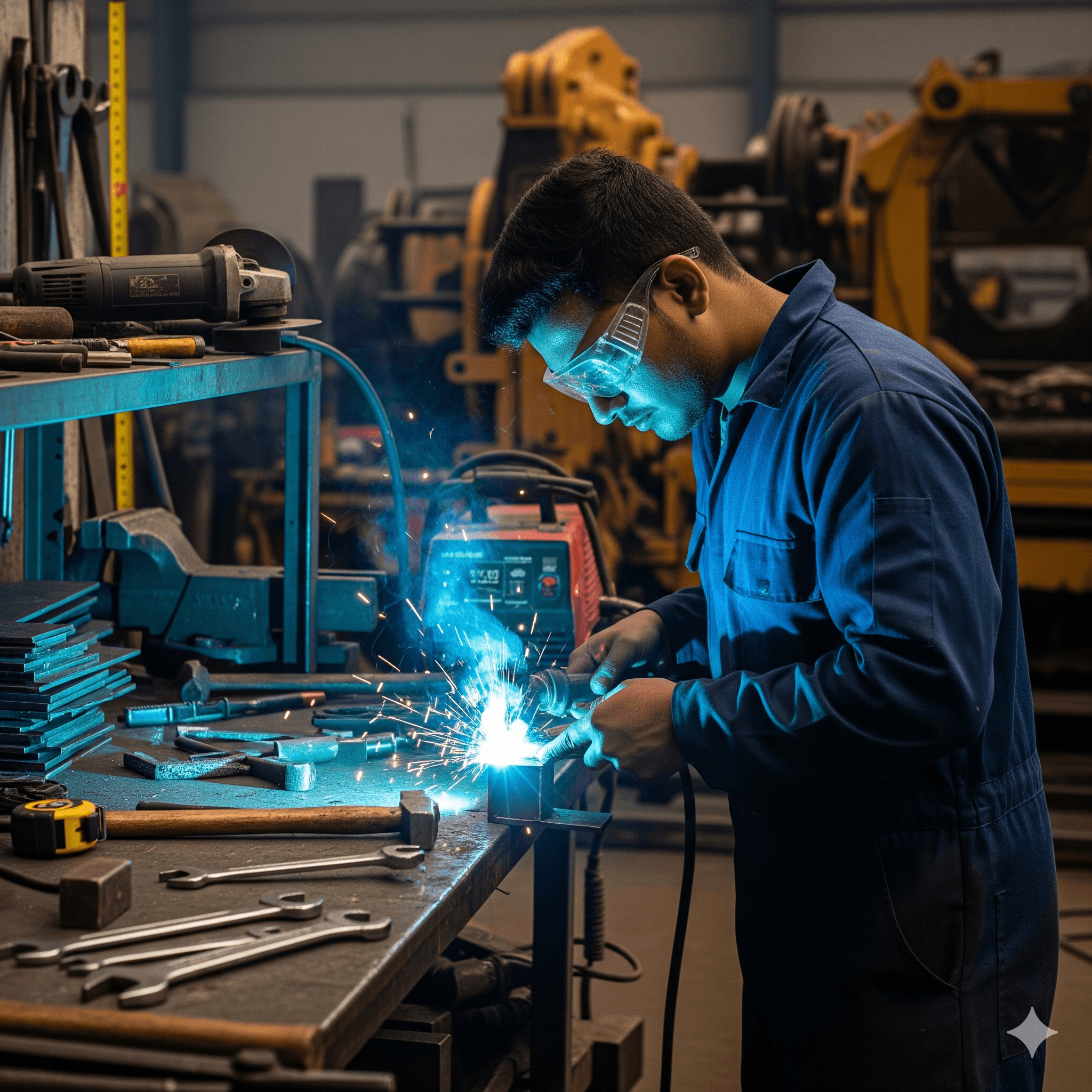

ACP fabrication involves processes like cutting, routing, grooving, and bending, each carrying its own set of risks. Ensuring safety is essential not just to protect workers, but also to deliver precise, defect-free installations.

1. Use of Personal Protective Equipment (PPE)

Wearing the right gear is non-negotiable: Gloves: Prevent cuts and abrasions while handling sharp ACP edges. Goggles: Shield your eyes from flying debris during cutting or grinding. Face Masks: Protect against inhalation of aluminium dust and fumes.

2. Workspace Setup & Ventilation

A clean, organized, and well-ventilated workspace minimizes risks: Ensure proper lighting for visibility during fabrication. Maintain clean floors to prevent slips. Use dust extraction units or industrial fans to remove airborne particles.

3. Material Handling

Store ACP sheets flat in dry, shaded areas. Use appropriate lifting techniques or tools to avoid back injuries. Always carry sheets vertically to avoid bending or damaging the material.

Master the Craft of ACP Panel Perfection

- SAW Cutting

- Grooving Machines

- Rout n Return System

- Bending with Press Brake

- CNC Cutting

SAW Cutting

Saw cutting is the first and most crucial step in Aluminium Composite Panel (ACP) fabrication. It involves using panel saws or running saws to achieve clean, accurate cuts without damaging the panel surface or core. For best results, it’s essential to use carbide-tipped (TCT) blades with a triple chip grind (TCG) tooth profile, which ensures smooth, chip-free edges. The cutting speed should be moderate, too fast can cause burning or melting, while too slow can dull the blade quickly. Always support the panel properly to prevent vibration or shifting during cutting, and consider using cooling systems like air or mist lubrication to reduce heat and extend blade life. To avoid rough edges or delamination, never use wood-cutting blades, and avoid cutting unsupported panels. A useful tip is to place a sacrificial board beneath the ACP sheet while cutting to prevent tear-out at the base. Following these practices ensures clean, safe, and efficient cutting, setting the foundation for precise fabrication.

Expert Tips for Flawless ACP Installation

Surface Preparation

Fixing Methods

Thermal Expansion Considerations

Common Mistakes to Avoid

Ensuring safety during ACP fabrication is essential not only for personal protection but also for achieving precise, high-quality results. Here are the most common mistakes to watch out for—and how to avoid them:

1. Improper Handling

ACP sheets can have sharp edges and be bulky. Without gloves, goggles, or proper lifting technique, injuries are likely. Always use personal protective equipment and handle panels with care to prevent accidents.

2. Incorrect Tool Usage

Using unsuitable tools like wood blades or dull cutters can cause rough edges, material damage, or kickbacks. Always choose the right tools, preferably carbide-tipped—for clean, precise, and safe fabrication.

3. Neglecting Ventilation

Cutting and routing produce dust and fumes that can harm respiratory health. Without proper ventilation or extraction systems, risks increase. Always work in well-ventilated areas and wear masks during fabrication.

Our expert technical team is standing by to assist with fabrication planning, wind load calculations, custom bending specs, fire compliance, and BIM modeling. Whether you're designing a high-rise façade or a curved architectural feature, we’ve got the engineering insight to ensure your project delivers flawlessly.